Cement Machinery Parts, Ball Mill Parts, Cast Steel ...

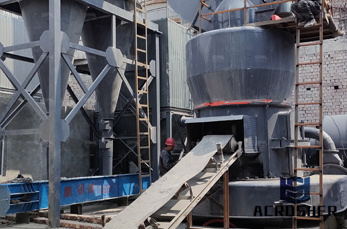

We can manufacture all kinds of vertical roller mill parts, ball mill parts, rotary kiln parts and other steel castings as per customers'' drawings and .

WhatsApp)

WhatsApp)

We can manufacture all kinds of vertical roller mill parts, ball mill parts, rotary kiln parts and other steel castings as per customers'' drawings and .

The milling process generates heat and excessive mill temperatures are undesirable. It is clearly helpful, therefore, if the clinker is cool as it enters the mill. From an environmental and a cost viewpoint, the cooler reduces energy consumption by extracting heat from the clinker, enabling it to be used to heat the raw materials.

parts of cement mill – Grinding Mill China main parts of cement mill parts for salemanufacturers A cement mill or finish mill is the equipment used to grind the hard nodular clinker from the cement kiln » Learn More cement mill parts How to Read .

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills. Chat Online; Parts Book Sharp Industries. Download PDF ...

Riyadh Cement Mill Pakistan Cement mill parts in gujranwala pakistan pcclas. cement mill parts in gujranwala pakistan pakistan wikipedia etymology. the name pakistan literally means "land of the pure" in urdu and persian. it is a play on the word pāk meaning pure in persian and pashto; the suffix .

• Formerly used as a swing mill in a cement plant • Reported capacity as dry raw mill: 220 t/h • Reported capacity as cement mill: 80 t/h OPC to 3700 Blaine • Effective grinding length 33''73/4" • Shell length inside flanges 36''31/8" • First compartment length 15''0" • Second compartment length 18''73/4"

Spare Partsmore>> Mill accessories. Other accessories. Conveyor. Cement packing storage. Vibrating screen. ... Cement mill. Vertical mill. Mine mill. Air swept coal mill. Superfine open flow slag mill. Surface peening processing mill manufacture enterprise. Mill sheel. Export Australia ball mill port shipment.

Moreover, the company also deals in Cement Mill Machine Spare Parts, Chemical Process Equipment, and Sugar Plant Equipment. The company is located in the medabad city of Gujarat and has successfully established its name in the entire Indian market, by offering its unmatched products. We are established manufacturer and supplier of various ...

MPParts has the fastest, friendliest service in the Concrete and Heavy Truck Industries. We are family owned and operated, whether you need Concrete Mixer Parts or an entire Concrete Batch Plant, MPParts has you covered. With over 65 years experience in the industry, we understand the importance of fast, accurate service to keep your concrete up and running.

More is better: More cement plant replacement wear parts, more alloy selection, more industry expertise. From pit to raw grinding, to preheater, kiln, and finish grinding, Columbia manufactures a full range of replacement parts for cement production.

Cement Place your mouse over the yellow or the blue mill parts to go to the relevant section The Group Industries has its origins in the cement manufacturing industry and its continued success in this sector has enabled it to continually develop new products that can be demonstrated to provide reduced maintenance costs and improved cost ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

SINOSPARE is a China leading cement spare parts manufacturer, maintenance repair operation (MRO) solutions provider for the cement industry. We offer rotary kilns, ball mills, roller press, stackers reclaimers, rotary feeders, telpic loading spouts, filter bags, dust collectors, storage vessels, finned tubes and heads for boilers, heat ...

We have replaced the conventional steel stand with a simplified concrete stand for the OK™ Mill. This allows standardisation of the mill''s mechanical parts, along with the use of the same construction procedure. Replacing the steel with concrete also .

Cement Mill Machinery Parts. Rs 38/ Piece Get Latest Price. We are engaged in providing an exclusive range of parts of Cement Mill Machinery that have easy installation features and are widely used in several industrial applications. They are made in stateoftheart facilities and are made of high quality materials of construction that are ...

Cement manufacturing spare parts. vertical roller mills wear parts; grinding mills wear parts; heat and wear resistant alloys castings; preheater and kiln spare parts; jaw plates, cones and hammers; alloys suit for cement manufacturing; wear parts for mining industry. ball mill grinding balls; ball mill wear resistant liners; dragline buckets ...

GRMK series Vertical cement mill have the ability completely to replace tube mill in the production of cement, for the reason, the cement specific surface area can be up to 3800 cm²/ g with stable and reliable quality. 2. Reducing the power consumption of cement .

TMS offers onestop solutions for cement and related industry''s mechanical equipment. Services include but not limited to overhauling, parts refurbishment, manufacturing and insitu repair of raw material processing machineries such as crushers and mill parts, coal mill, raw mill and cement mill components, material

Best Suppliers Of Parts For Cement Mill. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals ...

Ecorporates is your single source for supply and procurement of all equipment and spare parts for cement manufacturing. We also offer new installations, revamping and modifications of existing system in cement plants like waste heat recovery system and services related to clinker cooler, kiln, grinding.

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche''s pioneering engineering knowhow. CEMENT BLAST FURNACE SLAG CEMENT RAW MATERIAL

Mills » Products » CEMTEC. If the processing material is wet, cement mills can also be equipped with a drying chamber The drying chamber can be integrated into the mill or flangemounted to it It is equally simple to design the mill shell in one piece or in several parts (for transport reasons) Ball mills for,...

WhatsApp)

WhatsApp)