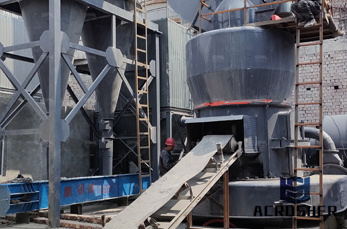

gold ore processing plant in Zimbabwe,gold ore smelting ...

Oct 21, 2019· Founded in Yantai, the capital city of gold in China, in the early 21st century, Prominer starts with the manufacturing of gold processing equipment .

WhatsApp)

WhatsApp)

Oct 21, 2019· Founded in Yantai, the capital city of gold in China, in the early 21st century, Prominer starts with the manufacturing of gold processing equipment .

A gold refinery, platinum refiners and silver smelters to recover old scrap gold at gold market prices. Buyers of karat gold to pure gold and gold bullion and all palladium, platinum and rhodium scrap metal including all precious metals.

Gold Ore Processing | ScienceDirect. The introduction of activated carbon to recover gold from cyanide leach solutions in the last quarter of the 20th century had a breakthrough impact on the economics of gold ore processing, as the world gold industry entered a period of unparalleled expansion following the deregulation of the gold price .

Heap leaching generally requires 60 to 90 days for processing ore that could be leached in 24 hours in a conventional agitated leach process. Gold recovery is typically 70% as compared with 90% in an agitated leach plant. Even with this inferior performance, the process has found wide favor, due to .

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing completely updated edition features coverage of established, newly implemented ...

Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality. In this way, it is necessary to have a better marketable product so that the incomes can be improved.

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

However, the value of ore or concentrate depends on the salable metal it contains, and the measure of profit or loss is the cost per unit of metal in relation to the price at which it can be sold. For gold and silver mines whose only product is bullion produced from amalgamation or cyanidation, it is relatively simple to set up unit costs on ...

Outotec DC Smelting Plant. Use a costefficient, sustainable, and compact solution for ferroalloys processing. Outotec''s direct current (DC) smelting furnace can be used for direct smelting of fine ores, even those with highly variable chemical or mineralogical compositions, as well as for recycling challenging byproducts such as steel dust.

The process design of gold leaching and carboninpulp circuits 14 JANUARY/FEBRUARY 1999 The Journal of The South African Institute of Mining and Metallurgy Figure 2—The CarbonInPulp (CIP) process Figure 1—ComputerAided Process Engineering (Cape)

Oct 22, 2019· Founded in Yantai, the capital city of gold in China, in the early 21st century, Prominer starts with the manufacturing of gold processing equipment and provide operation and maintenance service ...

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Oct 18, 2019· Garfield Refining has been refining precious metals since 1892 has an A+ BBB Rating. Refine your Gold, Silver, Platinum or Palladium with Garfield Today!

Gold Mining Board on Metals Place, a free gold mining Exchange. A gold mining trader''s only stop. Buy gold mining, sell gold mining and gold mining products on Metals Place gold mining marketplace, find gold mining producers, gold mining importers and gold mining exporters. Post your ad offer free!

A Poor Man''s Method of Smelting Gold ... You can remove the most common metals found in gold ore (copper, zinc and lead) using elements that bond with oxygen at lower temperatures than gold. This oxidation process will make copper oxide, zinc oxide and lead oxide — all of which are less dense than pure gold and will float to the top of your ...

Gold, silver, copper, lead, zinc, molybdenum, iron, potash, phosphate, and even sand for glass are often processed by froth flotation. Without froth flotation, many of the metals and minerals used every day in our modern world would be much more expensive. Solvent Extraction Solvent extraction is a hydrometallurgical process. The process entails:

fluctuating prices. Operating costs are the physical costs of producing copper: the direct and indirect costs incurred in mining, concentrating, smelting, and refining copper. They include transportation to the mill, smelter, and refinery, and metallurgical processing of the byproducts. Some estimates of operating costs also include the ...

Gold Ore processing plant Manufacturer India. Gold ore processing plants should be started with the feeder and it will take the extracted materials uniformly to the crusher for the first process. This process is used for resize and pulverize the gold ores into smaller than particles. Get Price

The introduction of activated carbon to recover gold from cyanide leach solutions in the last quarter of the 20th century had a breakthrough impact on the economics of gold ore processing, as the world gold industry entered a period of unparalleled expansion following the deregulation of the gold price .

Gold ore is a type of ore that can be obtained by mining gold ore rocks, requiring a Mining level of 40 or higher, and granting 65 experience. Gold ore can be smelted into gold bars through the Smithing skill, requiring level 40 Smithing. Gold bars can then be crafted to make various pieces of jewellery.

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as ...

Gold Refining. Gold mines process ore using various techniques to produce an alloy composed primarily of gold and silver, which is called a dore bar. The composition of dore can vary significantly between mines, but generally the gold dore bars the Perth Mint processes are composed of between 7080% gold and 1015% silver.

To perform direct smelting, a miner, community mining consortium, or processing shop employs a crucible, a high temperature bowl designed for smelting. Gold concentrate is combined with a flux, such as borax or other materials of mixtures, in the crucible. The flux acts to decrease the melting temperature and viscosity of nongold minerals in ...

WhatsApp)

WhatsApp)