THE CADIA HPGRSAG CIRCUIT – FROM DESIGN TO .

design that arise as processing issues later in this paper. ... ore to be fed to the SAG mill. The primary feed bin is at the hub of ore ... was to remove the ability to feed RoM ore direct to the ...

WhatsApp)

WhatsApp)

design that arise as processing issues later in this paper. ... ore to be fed to the SAG mill. The primary feed bin is at the hub of ore ... was to remove the ability to feed RoM ore direct to the ...

Mineral Processing Introduction MetSolve Laboratories Inc. Generally, mineral processing begins when an ore is delivered from a mine, to a, is applied directly on runofmine ores followed by the extraction of gold and in, The products from AG or SAG mills typically feed secondary grinding mills. Contact Supplier

FTB Infinity Ore Processing. MikrySoft Aug 10th, 2015 (edited) 602 Never Not a member of Pastebin yet? ... Dense Iron Induction Smelter Sand/Pyrotheum 8x Iron Ingot + 25%/75% 3x Nickel Ingot . Iridium Ore Induction Smelter Sand/Pyrotheum 2x Iridium + 5%/15% Rich Slag ... Certus Ore SAG Mill 1x Certus Quartz + 1x Certus Dust. Charged Certus Ore ...

If this is the case ( from stockpile) and you do not have a bypass conveying system, a metal detector and Jaw/Cone Crusher as a separate system for processing discarded material from SAG mill and recycle back to SAG mill via the feed conveyor then I can see that you now have a technically viable project for someone to design this process ...

Range of SAG, ball, and rod mills for capacities under MW. Mill control system. The optional Outotec mill control system features the latest in stateoftheart technology and is the preferred control option for all Outotec grinding mills.

Nickelcobalt mineralisation exists predominantly in the form of cobaltpentlandite, with trace amounts of vaesite. ... with crushed ore conveyed to a pit top bin from where the ore is conveyed either directly to the mill feed stockpile, or to secondary crushing. ... in the circuit to crush pebbles ejected from the SAG mills to minus 12 mm ...

COBALT PROCESSING DEVELOPMENTS K G Fisher Bateman Engineering Projects ABSTRACT ... the same time, the major source of feed material has changed and the metallurgical processes for cobalt recovery have been developed, adapted and improved over these ... Trend for SAG Mill .

2x+ Ore processing in FTB infinity? Are there any methods of 3x or more ore processing present in this pack? I searched and found a flowchart showcasing various mod''s 2x processing, but my TiCon smeltery works well enough that there''s little incentive to set up a different system for the same result. ... Ender IO SAG mill with dark steel balls ...

The crusher product feeds into a Crushed Ore Bin with a live capacity of approximately 12 hrs. The ore is reclaimed from the bin using three vibrating feeders. The primary SAG mill is m x m with a MW variable speed motor. During commissioning, the SAG mill was run in .

We offer autogenous (AG), semiautogenous (SAG), ball, rod, and pebble mills in sizes ranging from kWs up to 30+ MW. Our product range also includes a number of unique solutions, including the world''s largest acidresistant grinding mills, which can operate with extremely corrosive slurry.

The open pit is scheduled to be mined out by 2026. Mill production will continue with underground and stockpile feed until 2032. In addition to the open pit Mineral Reserves, there are Mineral Reserves at Rainy River amenable to underground mining. Underground Mineral Reserves have .

The concentrator was designed to produce 331,000 tonnes of nickel and 83,000 tonnes of copper concentrate each year. The plant included single stage crushing, with conveyors that deliver the ore to a coarse ore bin. Coarse ore is ground in a two stage grinding circuit that comprises a SAG and ball mill.

Nickel ore processing fine ore bin; IGMF Ore Handling and Storage Resources Gold Technology. Material handling equipment by Resources Gold Technology includes a series of coarse ore bins for receiving and storage of gold ore for feed to the crusher section of the gold ore processing facility. Following crushing the fine crusher product is ...

In a autogenous mill the ore is fed directly into the mill from either the primary crusher or the mine itself. The size of the rock will be between four and eight inches. It will be this type of mill that will use a stock pile instead of a bin as fine ore storage. The feed is large enough that moisture and freezing won''t bother it.

Sep 15, 2018· What is the best way to get Shiny metal?(direwolf20) Discussion in ''General FTB ... Your best bet is probably to run all your Ferrous ore through the TE Pulverizer or EnderIO SAG mill. Not sure which gets you more shiny dust, but I''d guess the SAG mill if you use flint or dark steel balls. ... use Tectonic Petrotheum to oretriple. Processing ...

processing plant for nickel ore. Nickel Ore Processing Plant Shanghai Zhongbo Direct Nickel (DNi) Process is a hydrometallurgical process for nickel laterite deposits. ... Accorrock to research, most nickel ore processing plants apply SAG mill, cone crusher, rod mill and ball mill during the nickel Grinding process to ...

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42'' () in diameter, powered by a 28 MW (38,000 HP) motor.

Dec 09, 2016· Accorrock to research, most nickel ore processing plants apply SAG mill, cone crusher, rod mill and ball mill during the nickel Nickel ore processing plant Mining, crushing, grinding

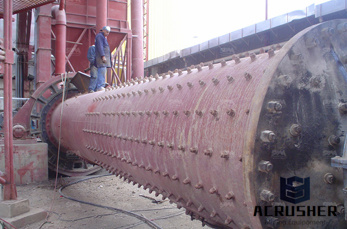

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Apr 23, 2014· Silk Touch pulverizing VS Fortune. ... there is an "average" 120% increase, which is better than processing, it turns out. Eruantien, Apr 21, 2014 #6. GWgameing1 likes this. ... EnderIO''s SAG Mill also gives you 3 coal and a decent chance of pulverized coal per ore, and 2 nether quartz + 1 dust per nether quartz ore. ...

Note that the curve exhibits the classic behavior of a SAG mill curve, showing the effect of the ore as the grinding media in coarse particles and the effect of balls, which begins to appear in the 50 mm particle size, having its greatest point at 7 mm. For all mills, the breakage rate indicates a profile with a welldefined inflection point.

2200 TPD Copper Lead Zinc Ore Processing and Recovery Plant ... SAG Mill Feed Weigh Scale Milltronics ... Coarse Ore Bin Feed Conveyor 36" X 340'' SAG Mill Feed Conveyor 30" X 160'' Jaw Crusher Feed Chute Jaw Crusher Discharge Chute Transfer Chute Coarse Ore Bin Feed Chute Apron Feeder Feed Chute Apron Feeder Dribble Chute

Dewatering is an important process in mineral processing. The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue.

suitable mill feed size – which varies according to the crushing/grinding circuit – can achieve up ... contain 515 weight percent of the ore feed, (directly related to ore grade). Depending on the specific mineral ... flowsheet development and processing assumptions based on limited testwork. A prefeasibilitylevel study is

WhatsApp)

WhatsApp)