JXSC China Gold Concentrator, Centrifugal Separator ...

JXSC Mining Equipment for sale! Complete mineral processing equipment, rock crusher, gold wash plant, magnetic separator, magnetic separators, flotation machine, etc.

WhatsApp)

WhatsApp)

JXSC Mining Equipment for sale! Complete mineral processing equipment, rock crusher, gold wash plant, magnetic separator, magnetic separators, flotation machine, etc.

The History of Grain Processing Corporation | Corporate info ... Production was then shifted from industrial to beverage alcohol. ... Our prominence in this area is a result of largescale efficiency and the ability ... the company came on stream with the initial stages of a corn wet milling operation. ... the GPC commitment to quality, MALTRIN ® products are the gold standard for the industry.

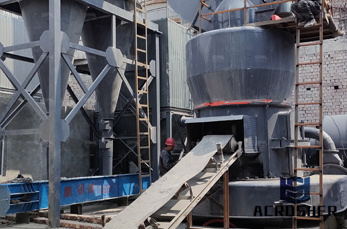

Home > Product >Ore dressing machine Rod Grinder. ... Rod grinder can be divided into dry rod mill, wet type rod mill and rotary rod mill according to working way; and can be divided into limestone rod mill and mineral rod mill according to types of materials. ... Rod mill has larger capacity than ball mill with same specifications. Relations ...

F. Delogu, G. Mulas, in HighEnergy Ball Milling, 2010. Fundamentals of mechanical alloying processes in ball mills. A ball mill is a relatively simple apparatus in which the motion of the reactor, or of a part of it, induces a series of collisions of balls with each other and with the reactor walls (Suryanarayana, 2001).

Nov 12, 2014· Offical website:【】 Alibaba website:【】 Product webpage:【 ...

Ball Mills vs Rod Mills AM King. PreOwned Mining, Processing Construction Equipment Since 1979 ... Ball mills and rod mills are both excellent mining machines for grinding ores into ... copper or other mining media than a rod mill may be a better fit than a ball mill. ... with upstream and downstream process equipment to complete your milling circuit.

overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30'' x 41'' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913. These heavyduty machines .

China Rod Mills Select 2019 Rod Mills products from verified China Rod Mills manufacturers, suppliers on

This fact should be carefully kept in mind when determining the capacity of a Steel Head BallRod Mill, as this unit can carry a greater ball or rod charge and has potentially higher capacity in a given size when the full ball or rod charge is carried.

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated research ...

[citation needed] But note that the term ''rod mill'' is also used as a synonym for a slitting mill, which makes rods of iron or other metal. Rod mills are less common than ball mills for grinding minerals. The rods used in the mill, usually a highcarbon steel, can vary in both the length and the diameter.

Introduction to ball mill machine: Fote ball mills or ball grinding mills are widely used for ore beneficiation of many industries such as cement, silicate product, new construction materials, refractory matter, chemical fertilizer, nonferrous metal and glass ceramic products etc. Ball mills can grind all kinds of minerals in both wet and dry types.

Electric Mill Wet Dry Grinder Machine For Corn Grain Wheat Coffee Cutter 110V. Was: ... √HEAVY SPEED √28000 R/MIN √2KG CAPACITY √70300 MESH. out of 5 stars. ... 1000G Electric Herb Grain Mill Grinder Multifunction Universal Mills High Speed. 8 left.

Autogenous Mill 【Introduction】: A wet autogenous mill that materials as grinding media 【Particle Size】: 200350mm 【Improvement】: Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball power consumption, no dust pollution, less auxiliary equipment, easy production automation ...

China Rod Mill Select 2020 Rod Mill products from verified China Rod Mill manufacturers, suppliers on

Rod mills are used in an open circuit between crushing and the ball mill. They often operate in wet and where the pulp contains up to 50% solid by mass. This machine is equally very applicable to dry where it could take a feed that has achieved 6% moisture. As such, when the product is sticky, rod mills are preferred over ball mills.

Figure Media motion in the tumbling mill. Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding action is induced by relative motion between the

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Grinding Equipment from Henan Xingkuang Machinery Co., Ltd.. Search High Quality Grinding Equipment Manufacturing and Exporting supplier on

Every mining operation has a unique grinding process. has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your mill.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

email: sales605 website: Processing ability:/h Feeding size:≤25mm .

WhatsApp)

WhatsApp)