MonoChamber Ball Mill Page 1 of 2

Re: MonoChamber Ball Mill. Hi Raj, Thanks for your reply. There is a hammer crusher before the raw mill so mill feed is very fine with d80 (80% passing size) of .

WhatsApp)

WhatsApp)

Re: MonoChamber Ball Mill. Hi Raj, Thanks for your reply. There is a hammer crusher before the raw mill so mill feed is very fine with d80 (80% passing size) of .

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

High Strength Double Chamber Small Cement Ball Mill For Sale, Find Complete Details about High Strength Double Chamber Small Cement Ball Mill For Sale,Cement Ball Mill,Cement Ball Mill,Small Ball Mill from Mine Mill Supplier or ManufacturerZhengzhou Shuguang Heavy Machinery Co., Ltd.

The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses; Calculators Online

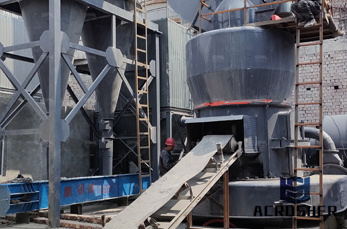

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** ... Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills ... Diaphragm Double blind plate Mill speed rpm GM in I chamber .

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential features of a model for mill .

single chamber cement mill Single Chamber Cement Mill A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into . again a problem, and roll presses are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill.

The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls. Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; Residence time of the material in the mill chamber. The size, density and number of the ...

Chamfer Cutters. Create a variety of different chamfering features with our hundreds of Chamfer Cutter options. Our pointed and flat end styles are available with multiple flutes and fifteen angles per side, giving you a diverse selection for chamfering, deburring, and back chamfering in various materials. Be sure to check out our Adjustable Chamfer Cutter, which quickly changes chamfer angles ...

Classification liner for the second chamber of the ball mill | Industrial ... The second chamber of a ball mill is mainly for fine grinding. ... Energy Efficiency and Resource Saving Technologies in Cement Industry ... was compiled by the APP Cement Task Force .

Single Angle Chamfering Cutters have a conical, tapering cutting head for milling at a 45° or 60° angle in dovetail work and angle cutting. Dovetail cutters are similar, but have an inverted cone which widens at the end for producing dovetail cuts. Double Angle End Mills (also known as Vslot milling cutters) have a diamondshaped cutting head profile with peripheral teeth, and are designed ...

Reducing the ball charge will reduce the grinding capacity, and the comment on installing a grate discharge is a good one as it will let ore out sooner, thus minimizing overgrinding, which will occur if the mill is (temporally) too big, or one chamber is too big in a multi chamber mill.

Application: Energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materials.

Re: Request for feedback for a Two Chamber Cement Mill Ball Charge and Longitudinal Sieve Analysis. As per your given mill details.(mill output assumed to be 45 tons / hr) for more details you can contact me at vikprocem . It is not so easy to .

Wet Grid Ball Mill . The wet grid ball mill is the key equipment for crushing the material after it has been crushed. This type of grinding machine is equipped with a .

the mill is equipped with a chamber and is mainly used in case of intended relocation, as well as at lower tonnagesurthermore, the plant is equipped with a feeder adapted to the mill for the feed material and a separate dedusting tec rocket mill rm 2 double. Get Price; Ball Mill,Ball Mill Equipment For Sale, Grid Ball Mill

Browsing for small ball mill for sale? The best online shopping experience is guaranteed! 8,431 small ball products from 2,810 small ball suppliers on for sale are available!Talk with suppliers directly to customize your desired product and ask for the lowest price, good discount, and shipping fees.

BeadMills | Vollrath . Doublechamberbeadmill. For large production runs where the required grind specification cannot be achieved in one pass or the output is low, the VOLLRATH doublechamberbeadmill type VMSM 2/..B is the best option. This mill is with 2 grinding chambers piped in series. SERVICE ONLINE GET PRICE

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

single chamber ball mills in cement industry. Application of Soft Constrained MPC to a Cement Mill Circuit single chamber . cement industry, MVR roller mills . mills is a process which consumes large . Get Price And Support Online; ball mills in cement industry. single chamber ball mills in cement industry. single chamber ball mills in cement ...

WhatsApp)

WhatsApp)