The Art and Science of Refining Gold at Home

Feb 12, 2016· The Art and Science of Refining Gold at Home. ... You''d be forgiven for thinking that things like the process of refining gold are complex and complicated procedures that can .

WhatsApp)

WhatsApp)

Feb 12, 2016· The Art and Science of Refining Gold at Home. ... You''d be forgiven for thinking that things like the process of refining gold are complex and complicated procedures that can .

Our Process. AGR offers smelting, assaying, refining, manufacturing and exporting services to its clients. We offer innovative and tailored services to meet each of our clients'' needs. Whether it is transportation, procurement or export, we will work to offer the best solutions to each individual client under AGR''s onestopshop model ...

As an independent private company, our shareholders are drawn from across the South African gold mining industry, placing Rand Refinery in a unique position. This gives us extensive insight and unique understanding of the precise requirements of both the mining process and mining houses, ensuring we fully meet our customers'' needs.

refining anode slime and from goldelectrowinning cathode sludge. Following the success of these trials, the first fullscale gold refinery to use this process has recently been commissioned. This refinery, at Randgold''s Harmony Gold Mine in the Free State Goldfields, is designed to refine 2000 kg of gold per month. The process

Refining of Gold with the Cementation Processes. Older Processes with Nitre. Older Processes with Common Salt. Refining Gold Bullion with of Oxygen or Air. Dr. T.'' Kirk Rose''s Experiments with Oxygen and Air. Work Done in Western Australia. Miller''s Process of Gold Refining. Equipment and Supplies. Furnaces; The Crucibles and Connections

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

The final stage of gold production refining involves removing impurities that remain after the smelting companies receive doré bars, as well as scrap gold, and reliquefy the metal in a furnace. Workers add borax and soda ash to the molten metal, which separates the pure gold from other precious and less precious metals. A sample is then taken to a lab for tests, or ...

HiTech Precious Metals Refinery operates one of the world''s most sophisticated and leading edge technology in the precious metals refining industry. HiTech''s proprietary process demonstrates significant efficiency, enhancing the speed of the treatment with an ecofriendly and short refining process.

Sep 16, 2007· How gold is produced, from excavation to ingotform. Gold extraction with BORAX for smallscale miners Rather Rich Healthy than Poor Poisoned Duration: 9:49. geusTUBE 1,014,152 views

To give the reader a complete picture of gold refining in South Africa, the historical development and all operations of the refinery are described in detail in this chapter, although some activities cannot strictly be defined as gold refining. Historical Development In the early days of South African gold mining, the crude bullion produced

Gold can be concentrated and recovered by applying different gold refining process methods and the final product has variable quality. In this way, it is necessary to have a better marketable product so that the incomes can be improved.

Gold Refining. Gold mines process ore using various techniques to produce an alloy composed primarily of gold and silver, which is called a dore bar. The composition of dore can vary significantly between mines, but generally the gold dore bars the Perth Mint processes are composed of between 7080% gold and 1015% silver.

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Gold is processed by cyanide milling, a chemical procedure that separates 95 to 98 percent of the gold from raw mined ore. It is then refined to the gold standard purity, according to Mineweb. Heap leaching is a less expensive method of gold extraction, but it is a longer process and it recovers less gold than the cyanide milling process.

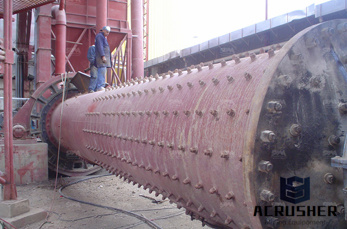

Gold Mining And Refinery Process . The miller process is a gold refining process that produces gold of for industrial processes like gold learn more supply gold mining and refining crusher equipment for sale gold mining and refining crusher xinhai is a manufacturer of construction and mining equipments in .

Hard rock mining is the process of using open pit or underground mining tunnels to retrieve the gold from the rock. The Gold ore is finely crushed rock or earth containing trace amounts of Gold which are extracted using a chemical process. The most commonly used chemical for this process is Cyanide.

The noble silver and gold remain in the elemental form, while the lead oxidizes and is removed. The gold and silver alloy thus produced is refined by the Moebius or Thum Balbach process. The residue from silver refining is treated by affination or parting to concentrate the gold content, which is refined by the Wohlwill process. From zinc ...

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

Jan 04, 2020· Some gold refineries buy lots outright, while others may pay people based on the value of the assay at the end of the process. The first step at a gold refinery typically involves weighing the lot. Lots can include recycled gold jewelry and product components, metal scraps, and so forth.

If you sold your gold to a pawn shop or other place, however, the pawn shop may send your gold to a refinery so that it can be tested and refined. The Refiner Takes a Sample; If the purpose is only to test the purity of the gold, the following process only requires a small sample of the gold.

Exploring for gold is a long process requiring significant time, money, and expertise. Learn about gold exploration and how mining gets started. Exploring for gold is a long process requiring significant time, money, and expertise. ... smelting and refining gold; The lifecycle of a gold mine; Responsible gold.

Jun 24, 2008· The Gold Value Chain Part II Refining ... The mining process gets gold up to a reasonable purity, but it is more efficient to give this to a refiner to get it to the acceptable % purity than for the miner to do it themselves. It is also easier for the gold industry as a whole to accredit the production processes of a few refineries than ...

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the .

The ancient process of refining gold has already been described under METALLURGY (which see). Most of the Bible references are to the refining of silver ... of the buildings connected with the mining and refining of the precious metal ... /g/ 57k. Pot (46 Occurrences)

WhatsApp)

WhatsApp)