iron ilmenite ore separation machine wet process drum type ...

Dec 05, 2017· JXSC website: , this video is about the wet process magnetic separator for removing iron and ilmenite, this drum type magnetic separator is with gauss, this magnetic ...

WhatsApp)

WhatsApp)

Dec 05, 2017· JXSC website: , this video is about the wet process magnetic separator for removing iron and ilmenite, this drum type magnetic separator is with gauss, this magnetic ...

Gravity separation spirals, gravity separation beneficiation typical applications of gravity separation sprials coal, gold alluvial or free, mineral sands rutile, zircon, ilmenite, tungsten, silica sand, chromite, tin, iron microfloatability of rutile and zircon with soap and amine type gravity separation at .

Magnetic Separation Of Slica Sand. Magnetic separation article of ilmenite and silica sand magnetic separation in sand processing 201683general traditionally the sand industry has not considered magnetic separation as a process alternative except in a few special applicationsthe sand deposits exploited to supply the glass and ceramics industries have until recently been of low

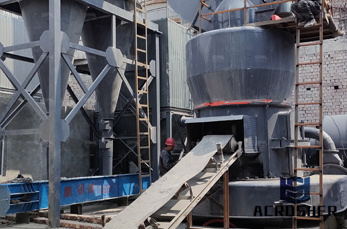

The basic silica sand making process and dust removal and impurity removal functions. For the high pure requirements of silica sand, highpurity extraction such as flotation, magnetic separation, and spot selection is also required. Silica sand processing plant and equipment. According to the production process, the equipment used in silica .

Ilmenite ore magnetic separator machine application in. Ilmenite ore magnetic separator machine application in. Ilmenite magnetic separator ilmenite magnetic separator is suitable for the wet magnetic separation of the materials whose granularity is below 3mm such as magnetite pyrrhotite calcined ore and ilmenite .

Using a magnetic separation method at various magnetic intensities, paramagnetic minerals, ilmenite ( T magnetic product), and monazite/xenotime (– T magnetic product) were recovered selectively. Using a magnetic separation result, the beneficiation process was conducted with additional gravity separation .

Typical ilmenite process flowsheet Figures 2a and 2b show basic examples of flowsheets for ilmenite processing including wet and dry magnetic separation. Figure 1. Comparison of magnetic separation technologies Figure 2a. Ilmenite .

Magnetic Separation in Sand Processing S. Fawell ... Generally where the iron is in the form of a discrete mineral such hematite, magnetite ilmenite chromite and biotite micas, physical separation processes work very well as the iron is in a ... Normally silica sand producers prefer to process material in the wet state to obviate the need for

Process Of Ilmenite And Silica Magnetic Separation. A discussion of magnetic separation techniques for concentrating ilmenite and chromite ores M. DOBBINS J. DOMENICO and P. DUNN Outotec USA Processing Physical Separation Magnetic separation .

process of ilmenite and silica magnetic separation Gold Ore Crusher. ... Magnetic separation: In silica sand mining process, various magnetic minerals » Learn More; separation process to remove feldspar and iron from silica. process of ilmenite and silica magnetic separation. ...

Process Of Ilmenite And Silica Magnetic Separation Centrifugal High Gradient Magnetic Separation Of. Centrifugal High Gradient Magnetic Separation CHGMS was creatively developed and in the present investigation was used for the concentration of fine ilmenite .

Gravity Separation For Silica Sand. Gravity separation for silica sand gravity separation of rutile and silica crushing kwale mineral sands project mining technology the project is expected to be one of the top producers of ilmenite and rutile in the the remaining zirconenriched sand is treated in a wet gravity separation .

In most cases, ilmenite concentrate cannot be obtained directly via magnetic separation, especially for ilmenite from igneous rock deposits. The combination of gravity separation and magnetic separation is quite efficient for the removal of most gangue minerals. Electrostatic separation

What Is Sand Mining Process Silica Sand Mining Process The whole silica sand mining process generally includes the following steps crushing Gravity Separation According to the different minerals density in the silica sand gravity separation is used to remove Magnetic Separation In silica . ... such as iron ore, ilmenite.

Pilotscale Demonstration Of Ilmenite Processing. Ten metric tons of Longnose ilmenite sample was beneficiated using gravity and magnetic separation to produce an ilmenite concentrate for hydrometallurgical testing The beneficiation process resulted in three final products high silica tailings magnetitetitanomagnetite concentrate and ilmenite concentrate

A typically lowgrade titanium sand was first ground and then processed by lowintensity magnetic separation (LMS) and high gradient magnetic separation (HGMS) to recover titanomagnetite and ilmenite, respectively; as the TiO 2 grade of the sand is low, the primary treatment of the sand by magnetic .

process of ilmenite and silica magnetic separation. The Mineral Separation Plant (MSP) uses screening, magnetic, electrostatic and gravity and also to make different ilmenite, rutile and zircon product grades to meet separation circuit which removes any remaining silica .

Aug 24, 2020· Considered as one of the richest mineral sand deposits, Pulmudai mineral sand reserve is known for Ilmenite, Rutile and Zircon. Currently, Sri Lanka exports these minerals soon after mining and separation. Over 60% of the mineral sand deposit in Pulmudai are Ilmenite.

Ilmenite And Rutile Ores Mining And Processing. process crusher Ilmenite To Iron Ore Ilmenite And Rutile Ores Mining And into ilmenite and nonmagnetic . ... Magnetic separator is suitable for the wet magnetic separation of the calcined ore and ilmenite .

Magnetic separator is widely used for separation of Iron, magnetite, hematite, ilmenite,Manganese ore, chromite ore, tin ore, wolframite ore, coltan ore,ect. Some times for upgrading nonmagnetic minerals (such as zircon sand, silica .

When you need magnetic separation the Reading range of magnetic separators has a wide range of proven, cost effective products. Including wet high intensity, induced roll, rare earth roll, rare earth drum, low intensity and medium intensity magnetic separators the Reading range has a magnetic .

The remaining nonmagnetic, creamcoloured mineral fraction is a mix of silica sand, rutile and zircon sand, which is separated using electrostatics, froth flotation and density separation. Rutile is used in the production of tioxide (via the Chloride route); zircon sand is commonly used in ceramics; and silica .

Process Of Ilmenite And Silica Magnetic Separation. A discussion of magnetic separation techniques for concentrating ilmenite and chromite ores M. DOBBINS J. DOMENICO and P. DUNN Outotec USA Processing Physical Separation Magnetic separation has long been used to .

stateoftheart process technology complex mineral composition ... 70% of ilmenite concentrate for the whole country of silica sand for Siberian market. Ilmenite. is a feedstock for production of: .

WhatsApp)

WhatsApp)