Multimpact™ Hammer Mill Technology YouTube

Sep 09, 2016· is a leading manufacturer of food and animal feed processing equipment. Our hammer mills, with a reputation for high quality and cutting edge technology, have been the solution of choice ...

WhatsApp)

WhatsApp)

Sep 09, 2016· is a leading manufacturer of food and animal feed processing equipment. Our hammer mills, with a reputation for high quality and cutting edge technology, have been the solution of choice ...

May 29, 2018· Tietjen produces 48 types of hammer mills that are optimized for every purpose, from high speed mills to big chamber mills and wide chamber mills. The machines operate .

A hammer mill grinder is designed to reduce bulk material into smaller pieces, either by crushing or shredding. They are an important machine in many industries, including the mining, lumber and waste management industries.

Gold ore hammer mill hammer crusher is widely used to crush mineral ores medium or finely with, portable hammer mill for gold ore rrcserin, Get Price how to operate a hammermill for gold ore operation of conventional hammer mills and can be used to mill monly Hammer mill, design, testing, solid mineral processing, Nigerian . Oline Chat

Dwell Earth has developed the most productive, yet affordable Hammer Mill Grinder to run and operate. The GME14 Hammer Mill Soil Crusher makes grinding up soil clumps, rocks, and minerals easier than ever before. Learn more about the enhanced features, benefits, and cost of the soil pulverizer machine.

Dec 18, 2012· 150, 12″ Swing, Metal Lathe, Mill, and Drill . Almostfree metal lathe, drill and milling machines. Accurate and scalable to any size. Technology used has been proven for almost 100 years. Easily made from scrap, steel bar and concrete. Built with common hand tools, a .

How to operate 420 hammer mill machine? YouTube. Jul 10, 2013 The working principle of hammer mill crusher is simple, the raw materials are delivered through the feed hopper into the grinding chamber and crushed by the high speed operation hammer, under the ...

Hammer mills use rotating hammer or knives to breakup wet or dry product that has been fed into the chamber of the machine. The rotating hammers or knives in the chamber of a hammer mill reduce the side of the product by impacting the product and by forcing the product to .

Build Your Own Hammer Mill. Just follow our stepbystep plans and you''ll be making pellets from leaves, hay, straw, grass, paper, etc. Or just use it to mulch your yard debris! This Hammer Mill / Mulcher will reduce your yard waste so you can turn it into burnable pellets for heat.

The design structure of the hammermill is always determined by the end use. History. Water powered trip hammer mills were created in 488 AD by the medieval Chinese mathematician and engineer Zu Chongzhi which was inspected by Emperor Wu of Southern Qi (r. 482–493 AD).

What Is a Hammer Mill Used for? Main application of hammer mill. Apart from being able to crush coal, gypsum, tile and brick, as well as limestone and etc, hammer mill is capable of playing a crucial part in a crushing plant and sand making plant even replacing a cone crusher in an ore beneficiation plant. Pros and cons of hammer mill

the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from

Diesel hammer mill. Diesel engine hammer mill is used to crush the wood and biomass materials and reduce their size. As we know, to make biomass pellets, the size of raw materials should be 35mm. This hammer mill is driven by a diesel engine, whose powers are from 15hp to 55hp.

Hammer Mill Operating Principle We have never subscribed to the idea that the hammermill is suited to the primary breaking of shovelloaded, quarryrun, or ROM minerun rock and ore. Even though the material be nonabrasive and quite friable there are other machines which are better fitted for such work.

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

routine maintenance of Prater''s Full Screen Hammer Mill, Model #''s G5, G6, G7,G8. Since each Full Screen Hammer Mill is engineered for a specific application, there may be unique features in your particular machine that are not covered in this manual. Refer to this manual before beginning, and during installation. Keep the manual

You can use the hammer mill machine for primary, secondary and tertiary crushing. What do I mean here? You can use small hammer mills at the level using the standard current. Hammer Mill Working Principle. This is also another principle that would be of interest to know especially if you''re using this machine for the first time.

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

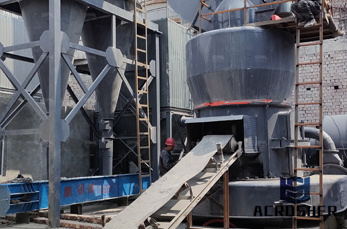

mtm grinding mill construction Mineral Processing EPC. Hammer Mill Design,Coal Hammer Mill,Impact Hammer Crusher, Find Complete . mill is widely used in metallurgy, mining, chemical, cement, construction, .. from YGM series to MTM trapezoid mill with improved singlemachine yields.

Hammer mill machine Introduction. The hammer mill machine mainly smashes grain such as peanut, soybeans, corn, wheat and cut grass or straw. The raw material is pulverized by a highspeed rotating of blade and hammers.

How to operate 420 hammer mill machine? YouTube. Jul 10, 2013 The working principle of hammer mill crusher is simple, the raw materials are delivered through the feed hopper into the grinding chamber and crushed by the high speed operation hammer, under the ...

Hippo No. 47 Hammer Mill with Air Conveyor. Hippo hammermills rapidly pulverize a wide range of materials from grain, beans, herbs and fibrous roots to minerals, plastics, glass, bone and recyclables.

Diesel engine machine is suitable for areas short of electricity or areas inconvenient to connect electricity. Wood hammer mill with diesel engine can process biomass materials into mesh size 210mm. Diesel engine machine is suitable for areas short of electricity .

DESCRIPTION: A hammer mill is a machine whose purpose is to crush ... This mill has the advantage of the continuous operation because the chance of... Get Price. How Does a Hammer Mill Work? ThomasNet News. Mar 14, 2012 ... The simplest way to describe the concept of size reduction is to look at the industrial hammer mill model. Hammer mills ...

WhatsApp)

WhatsApp)