Cement Plants located in Pakistan The Global Cement Report

Cement Plant Location Information for Pakistan. Cement plant locations and information on Pakistan can be found below. For full access to the database, purchase The Global Cement .

WhatsApp)

WhatsApp)

Cement Plant Location Information for Pakistan. Cement plant locations and information on Pakistan can be found below. For full access to the database, purchase The Global Cement .

Analysis of Pakistani Cement Industry – A Report. ... At present there are more than 28 cement plants in Pakistan with installed capacity of over million tonnes per annum. The present demand for cement in Pakistan is around million tonnes per annum. ... INPUT COST STRUCTURE .

Get corrections from Grammarly while you write on Gmail, Twitter, LinkedIn, and all your other favorite sites. From grammar and spelling to style and tone, Grammarly helps you eliminate errors and find the perfect words to express yourself. Grammarly allows me to get those communications out and ...

To improve energy efficiency in industry, lowgrade heat recovery technologies have been advanced continuously. This chapter aims to provide a basic understanding of stateoftheart technologies for lowgrade heat recovery and utilization in industry, which are developed based on the concept of thermodynamic cycles. The technologies include adsorption, absorption, liquid desiccant, organic ...

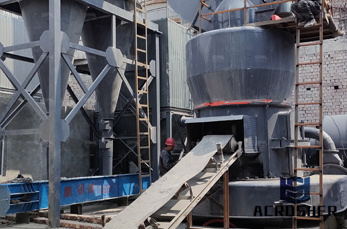

High Efficiency Tertiary Crusher|Fine CrusherStone ... The highefficient tertiary impact crusher is a fine crusher that is researched to be suitable for mediumhard materials by absorbing the advanced technology at home and abroad and combining the actual working conditions in domestic cement industry, mining, .

This paper presents an overview of the absorption cycles proposed in the literature for producing combined power and cooling. The dual output nature of these cycles makes it difficult to evaluate their performance so the various criteria used in the literature are presented and discussed.

"Principles of Exterior Drainage ... industry that has been so generous to the employee owners of NDS, Inc. The information in this manual is intended as a guideline for exterior drainage. A landscape architect or engineer should be consulted in critical areas ... Perhaps the most efficient is soil mapping information provided by the

A concrete mixer (often colloquially called a cement mixer) is a device that homogeneously combines cement, aggregate such as sand or gravel, and water to form typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to ...

An active recovery of the industry is occurring largely through the implementation of reconstruction and modernization projects at existing cement plants. Ukrainian cement producers have attempted ...

offers 1,203 cement plant in pakistan products. About 70% of these are brick making machinery, 8% are concrete batching plant, and 4% are prefab houses. A wide variety of cement plant in pakistan options are available to you, such as hollow block making machine, pocket filter.

How the cement industry is helping India meet its climate goals Given the cement industry''s achievements in energy efficiency and use of fly ash and steel industry slag, taking alternative fuel ...

As part of the IndustryWeek 2008 Salary Survey, we asked the openended question: What is the biggest challenge facing the manufacturing industry today?. Following are nearly 1,000 anonymous responses from IW readers, expressing in no uncertain terms what exactly is at the top of their todo lists. (Comments have been lightly edited, mostly for clarity).

Waste Heat Recovery Power Generation Systems for Cement Production Process Article (PDF Available) in IEEE Transactions on Industry Applications 51(1):1319 · January 2015 with 4,264 Reads

Robust construction activity has led to local cement producers increasing capacity at a breakneck speed. The country''s largest producer, Bestway Cement, informed the Pakistan Stock Exchange in March 2017 that it will set up a brownfield cement plant with a capacity of 6000tpd clinker at its Farooqia site in northern Pakistan.

Everyone is well aware of the importance of measuring electrical parameters correctly to help us make the right decisions regarding energy efficiency and its consequent shortterm costeffectiveness, but we often find that not only is it necessary to perform energy audits to quantify the energy consumed by our different installations, but power quality or transient events must also be detected ...

This applies in particular to carbon CCS technology due to its high cost. The projected cement production of a particular cement plant is presented through four different scenarios. The first scenario, businessasusual or BAU, can be considered as a reference scenario since the actual cement plant Emergy and Ecological Footprint are calculated.

Our turnkey solutions include all the components of the systems we build, completely customized starting from the detailed analyses of the functional areas of the site, involving the plant manufacturing and the development of the automation control, specifically designed to meet the requested performances.. Our specialized technical organization allows us to be the sole point of reference.

Jose A. Llontop is the new CEO and president of Giant Cement Holding, Inc. (GCHI), subsidiary of Cementos Portland Valderrivas, Madrid, Spain, and oversees GCHI''s American operations with plants in Alabama, Maine, Pennsylvania and South Carolina.

Ductwork typical cement plant pressure drops are: 60% to 80% of high temperature process duct work pressure drop occurs in the process equipment, baghouses, mills and cyclones. Since motor 1 (one) horsepower cost roughly 1000/year (US) (2005), duct efficiency is important.

Cement and steel are the building blocks of infrastructure. Given the projected growth in demand for infrastructure, especially in emerging economies, it will be essential to reduce emissions from the cement and steel industries, 17 which account for roughly 10% of total emissions. 18 Many cement and steel companies are making use of more efficient technologies to achieve cost savings ...

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces is the most widely used material in existence and is only behind water as ...

May 06, 2017· The contribution of cement industry is very effective not for only the manufacturing sector but also for the entire economic development of Pakistan. The cement industry of Pakistan was once a very small industry but it rapidly grew with the passage of time and finally it .

PREMIUM EFFICIENCY MOTOR SELECTION AND APPLICATION GUIDE | i ACKNOWLEDGMENTS The Premium Efficiency Motor Selection and Application Guide and its companion publication, Continuous Energy Improvement in MotorDriven Systems, have been developed by the Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy (EERE) with support from the .

Carbon sequestration is the process involved in carbon capture and the longterm storage of atmospheric carbon dioxide or other forms of carbon to mitigate or defer global has been proposed as a way to slow the atmospheric and marine accumulation of greenhouse gases, which are released by burning fossil fuels.. Carbon dioxide (CO2) is naturally captured from the atmosphere .

WhatsApp)

WhatsApp)